The Aqua Power technology has been developed over four decades. Each year, improvements have been made to ultimately arrive at the technology utilised today. Historically, the Aqua Power was developed to meet the fresh water needs of the world. As a result of further research and development, a method has been developed to convert the waste stream extracted through the mechanical water purification process to fuel and to ultimately convert that fuel to alternative power.

This propriety process and technology was designed to be a self-sustained, self-powered system that could be remotely operated, controlled and monitored with little or no annual maintenance required. This system is capable of removing any contaminant from any water source in massive volumes, replenishing the essential bloodstream of Mother Earth. The self-powered component is what sets this system apart from any other similar or claiming-to-be-similar system in the world.

The system removes from the input water:

- Contaminant hydrocarbon substances, dissolved gases and volatile substances

- Industrial pollutants, solvents, dyes, petrochemicals and metallic impurities

- Patented process detects and removes all nuclear and radioactive substances

- Microbiological contaminated substances, including parasites, protozoa, bacteria, fungi, spores, all forms of viruses

- Herbicides, pesticides and fungicides are also removed

- Industrial pollutants, solvents, paints, petrochemicals, contaminateing hydrocarbon and volatile substances are removed, as well as the dirt from the public sewer systems

Aqua-Power working method:

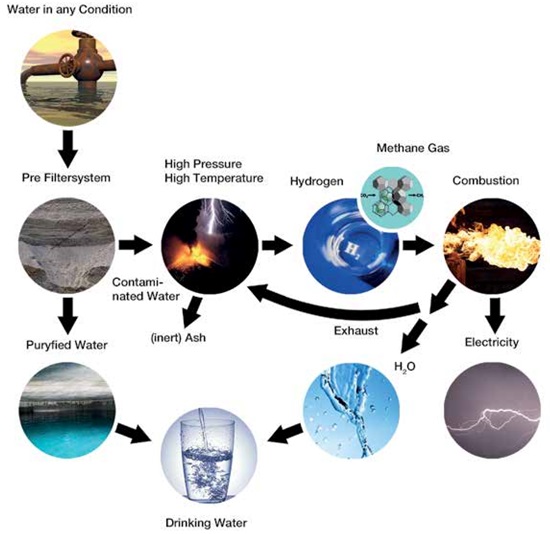

The equipment we develop, with the original function, which is used in Aqua Power, purifies the water and converts contaminated water at high speed into drinkable water. The focus of this summary is directed to the fuel extraction, energy production, and the combination of the two ways that allow the Aqua Power Water-Force Unit to be situated at any point in the world where water is to be found, and which can be used to produce drinking water and electricity, permanently and continuously.

Aqua Power accomplishes this task through mechanical purification. Aqua Power does not use membranes for this process-eliminating costly maintenance. The system takes the waste stream separated from the purification process and treats that waste stream through a proprietary plasma system that breaks the molecular covalent bonds converting solids and gases into their elemental forms.

The technolgy allows the separation of the respective elements which are then utilised as fuel, with non-desired elements (which are inert) being safely disposed of. The fuel for the separation is a syngas which Aqua Power utilises as clean fuel to power its turbines, which turns a generator that, in turn, creates power for the own system and additional surplus energy for the grid.

Aqua Power working scheme: